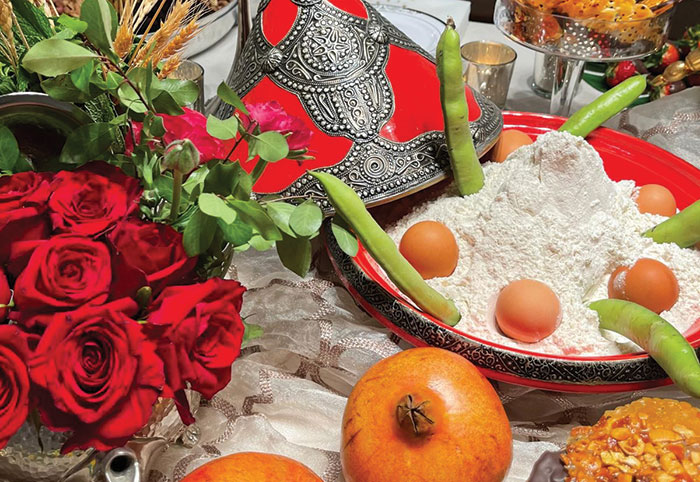

College student Jared Hasen-Klein, a volunteer with the SoCal Makers COVID-19 Response Team, prints PPE with his personal 3D printer. Photo courtesy of Hasen-Klein

College student Jared Hasen-Klein, a volunteer with the SoCal Makers COVID-19 Response Team, prints PPE with his personal 3D printer. Photo courtesy of Hasen-Klein

When Jared Hasen-Klein’s Washington, D.C., internship prematurely ended in March because of the coronavirus, he returned to his native Los Angeles. The Milken Community Schools graduate and current Cal Poly Pomona junior wasn’t sure what he would do aside from spend some unplanned quality time with his family, and maybe get a jumpstart on work related to his summer job.

Then he received a request from someone he knew from the FIRST (For Inspiration and Recognition of Science and Technology) community, a robotics organization with which he has been involved since middle school, first as a competitor, then as a volunteer. Specifically, he was asked if he could fix a couple of pages on the recently launched website for the SoCal Makers COVID-19 Response Team, a group started by another person he knew of through robotics. Hasen-Klein said yes.

“The next thing I know, they send me a Slack invite for the team,” Hasen-Klein told the Journal. “I open it up. They put me on the project-leads channel. So, I am now a lead.

Fortunately, the 20-year-old had the time and inclination to jump in. Since the SoCal Makers COVID-19 Response Team was started in March by Boeing engineer and longtime FIRST mentor Eric Gever, a Cypress resident, the group has grown to more than 150 volunteers − many of whom are high-school or college students like Hasen-Klein. The group has provided more than 15,000 pieces of personal protective equipment (PPE) to health care workers at upward of 125 hospitals, medical facilities and senior residences.

“When I came in, they were in the position where there was a lot of demand and a lot of people helping out, but there was not an organizational system in place,” Hasen-Klein said. “People were finding him on Facebook or on GoFundMe. He would have to distribute requests to volunteers. I helped out a lot with the request process and project management.”

A couple of weeks ago, Hasen-Klein purchased a used 3D printer so he could join the ranks of response-team volunteers making PPE. Initially, he was printing the masks individually. But he figured out a better technique. Now, he said, “I can stack them so it makes more than one at once. My machine makes 16 every 12 hours.”

Under normal circumstances, people making PPE in their homes for hospital use would not be possible, he explained. “But since this is an emergency situation, the FDA has decided to allow homemade PPE during the emergency declaration. The NIH (National Institutes of Health) also released guidance, including what designs work and tips like that.”

Hasen-Klein added, “We had someone approach us, someone making a lot of these shields. They asked, ‘How are you getting hospitals to approve these? I’ve been trying for weeks.’ I was thinking, we’re nothing but a group of individuals, but us being this large group has given us a little more reputability in this space.”

Gever’s home in Cypress (near Long Beach) along with the residence of another team member in the South Bay serve as hubs for volunteers to pick up raw materials. Some volunteers are exclusively dedicated to cleaning and sanitizing the masks prior to them being packaged in sets of 10. The PPE is provided free to local health care organizations that submit requests via the website. Organizations farther afield also may request the PPE. They are asked to pay just for shipping.

As of June 1, the team has raised upward of $20,000 from nearly 300 donors via its GoFundMe page. These funds are used to purchase the materials needed to make the masks and cover the costs of any replacement parts for the various, privately owned 3D printers operating around the clock.

When Hasen-Klein came on board, demand for the masks exceeded their ability to turn them out. But a growing volunteer force has meant increased productivity − and just in time. Hasen-Klein anticipates a new wave of requests as dental offices and others begin to reopen.

The 100%-volunteer enterprise has not been without challenges. “The past few weeks, there have been some shortages of certain types of plastic we need,” Hasen-Klein said. “No one has managed a supply chain before. No one knows what to expect with demand. The news is changing daily. So we never know what’s going to be needed.”

But Hasen-Klein is confident in the group’s ability to continue the important work. “What I have seen is the FIRST robotics community is always able to respond to situations,” he said. “The community is extremely creative.”

More news and opinions than at a Shabbat dinner, right in your inbox.

More news and opinions than at a Shabbat dinner, right in your inbox.