Cardboard bicycle can change the world, says Israeli inventor

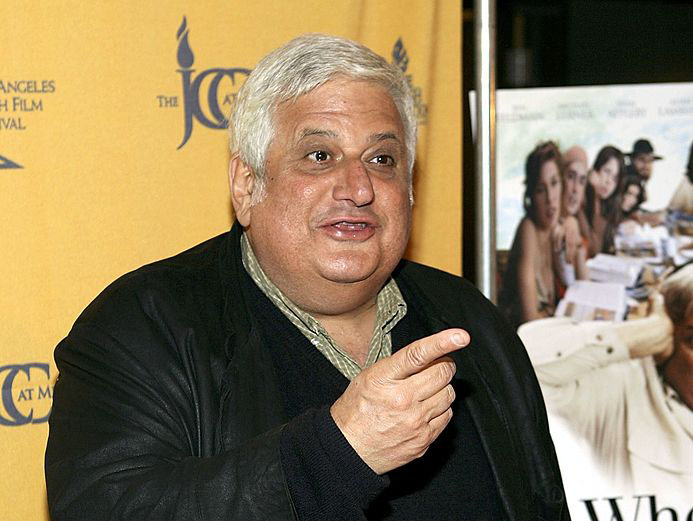

A bicycle made almost entirely of cardboard has the potential to change transportation habits from the world\’s most congested cities to the poorest reaches of Africa, its Israeli inventor says.

More news and opinions than at a Shabbat dinner, right in your inbox.

More news and opinions than at a Shabbat dinner, right in your inbox.